Modeling, Evaluation and Optimization of Interlocking Shell Pieces

Abstract

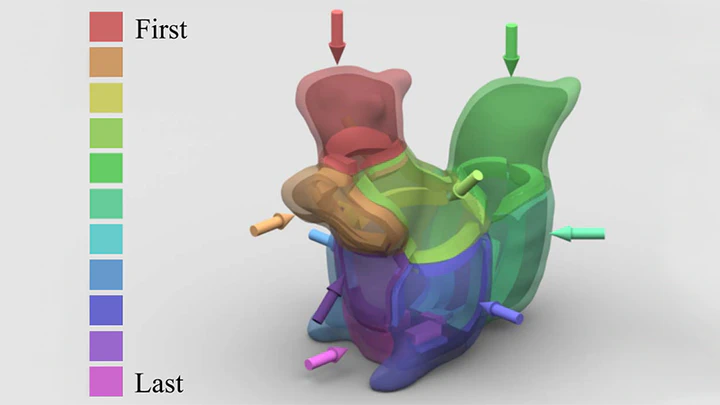

While the 3D printing technology has become increasingly popular in recent years, it suffers from two critical limitations: expensive printing material and long printing time. An effective solution is to hollow the 3D model into a shell and print the shell by parts. Unfortunately, making shell pieces tightly assembled and easy to disassemble seem to be two contradictory conditions, and there exists no easy way to satisfy them at the same time yet. In this paper, we present a computational system to design an interlocking structure of a partitioned shell model, which uses only male and female connectors to lock shell pieces in the assembled configuration. Given a mesh segmentation input, our system automatically finds an optimal installation plan specifying both the installation order and the installation directions of the pieces, and then builds the models of the shell pieces using optimized shell thickness and connector sizes. To find the optimal installation plan, we develop simulation-based and data-driven metrics, and we incorporate them into an optimal plan search algorithm with fast pruning and local optimization strategies. The whole system is automatic, except for the shape design of the key piece. The interlocking structure does not introduce new gaps on the outer surface, which would become noticeable inevitably due to limited printer precision. Our experiment shows that the assembled object is strong against separation, yet still easy to disassemble.

Type

Publication

Computer Graphics Forum (Pacific Graphics), 36(7)